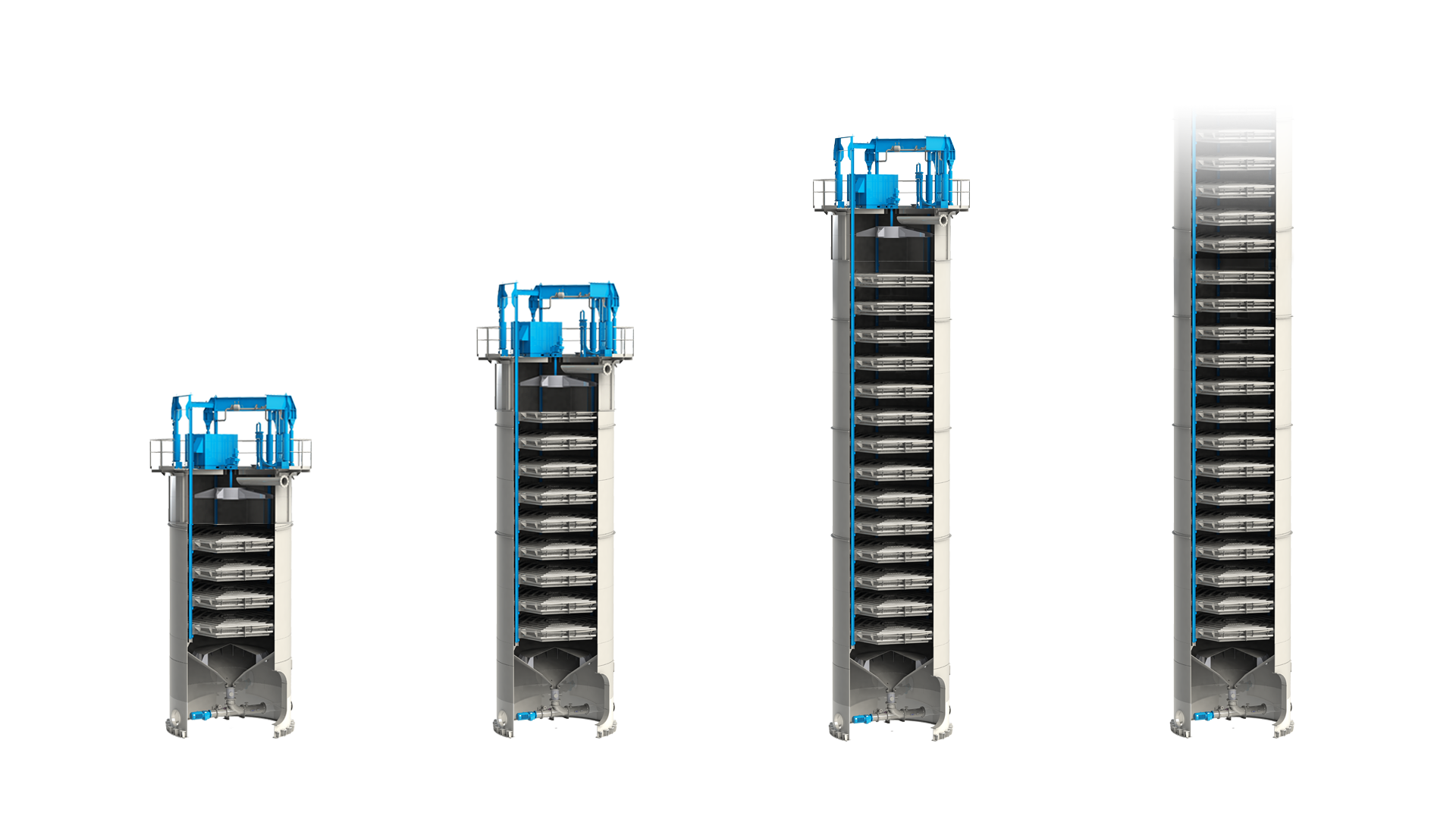

OVC

The cooling crystallizer

A new generation of efficient coolers. Perfectly equipped for constant crystal growth and maximum yield.

Scroll down and watch our product presentation.

A new generation of efficient coolers. Perfectly equipped for constant crystal growth and maximum yield.

Scroll down and watch our product presentation.

Molasses, one of the by-products of a sugar factory, is the mother liquor from the centrifugation of C-product. Molasses from cane sugar factories contains approx. 35 % sugar, from refineries approx. 40 %.

Some of this sugar in the molasses can be extracted using the OVC. Very quick ROI due to different price levels (sugar –molasses).

While crystallisation in vacuum pans for A, B and C-product occurs because of water evaporation, crystallisation in the OVC is brought about by cooling down the massecuite from the C-product vacuum pan.

Massecuite contains crystals and mother liquor. During the cooling process, crystal size increases, while the number of crystals remains the same. The purity of the mother liquor drops with a decrease in temperature (less sugar in the molasses).

mild steel

mild steel

optional:

optional: